8g. Soap Stamping Machines

Soap Manufacturing > 8. Soap Finishing Line

SOAP PRESSES

Soap machines manufacturers produce different models of soap press, also

called soap stamping machines. Depending by the final shape of soap bars, the soap

press are mainly divided in:

FLASH-STAMPING SOAP PRESSES

A flash-stamping soap press is used to produce bandless (soap without

side band) and banded (soap with side band) toilet soap bars. The machines

produce soap bars in a weight range from 10 up to 200 grams, in same case also

bigger soaps.

In the past the most diffused automatic soap presses assembled a

vertical rotating star with one or two cavities. The soap mould, called

die-set, was composed of two matrices approaching and moving away from the

star. This type of soap presses was used for many years but, due to the not

optimal finishing of the soap bars, these machines was replaced by the

horizontal and vertical flash-stamping soap press.

The first fully automatic vertical flash-stamping soap press was called

"Condor" and was invented in the middle of the last century by an

Italian company specialized is soap stamping machines. This machine was the

ancestor of the modern vertical flash-stamping soap presses that are used today

in soap industries.

8. Soap Finishing Line

8b. Soap Refining

8c. Mixers

8d. Soap Roll Mills

8e. Plodders

8f. Soap Cutters

8g. Soap Presses

8h. Chillers

8i. Accessories

8c. Mixers

8d. Soap Roll Mills

8e. Plodders

8f. Soap Cutters

8g. Soap Presses

8h. Chillers

8i. Accessories

>> INDEX

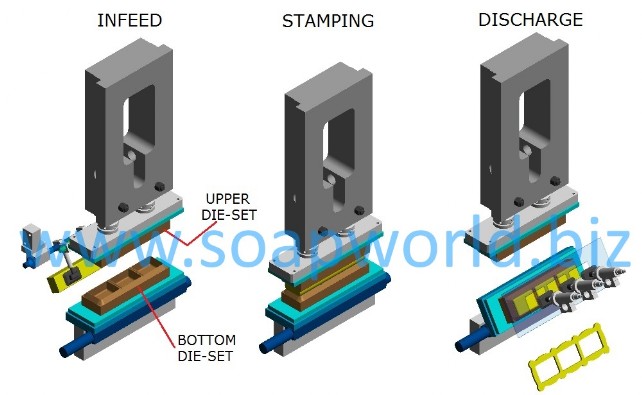

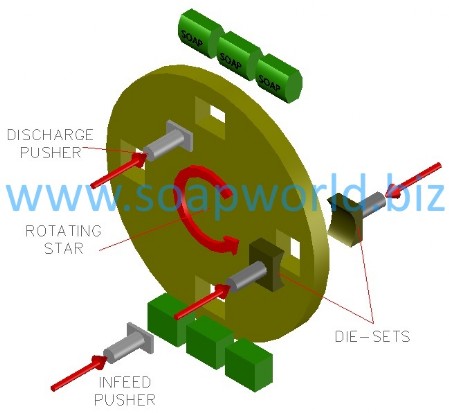

SOAP PRESSES FOR SOAPS WITH SIDE BAND

This type of soap presses are able to produce rectangular laundry soap bars, starting from rectangular soap bars that must be cut with the exact final weight because there is not flashing during the stamping.

The rotating star has four stations each one with one cavity; each stroke gives one stamped

soap bars. When a big production is required, each station has two cavities; in this case each stroke gives two stamped soap bars.

These soap stampers in general are able to work at 90 strokes per minute. The die set is composed by the rotating star, the 2 inserts and by the 2 pushers, one for soap feeding and another one studied to push out the stamped soap bars.

SOAP PRESSES FOR CUBIC SOAP BARS

A special soap press to produce cubic soap stamped on 6 faces, like Marseille Soap was invented before the middle of the last century. In that period Marseille soap was very diffused and there was the necessity of an automatic production.

This special soap stamper is still sold in this period and it is used in developing African countries.

This is a vertical soap press with a special die-set composed by the upper die-set, the bottom die-set and a fixed die-set that includes the 4 lateral inserts. During the stamping stage, a level moves the 4 lateral insert in the same time. When the upper die-set moves up, the lower die-set extracts the stamped soap bar.

HOTEL SOAP PRESSES

Small hotel soap bars, from 10 up to 30 grams, can be produced using a

specific type of soap press or also using a flash-stamping soap press. Specific

models of soap presses, with short movements were studied to stamp hotel banded

soap bars with a rate production of about 300 soaps per minute. This type of soap

press usually assembles a horizontal rotating star with only one small upper

die-set and bottom die-set. These soap presses are not flexible machines,

because they are studied to produce only small soap bars, but they are small

and cheaper stamping machines compared with flash-stamping soap press.