8f. Soap Cutting Machines

Soap Manufacturing > 8. Soap Finishing Line

SOAP CUTTERS

Soap cutter is installed after a Plodder to cut the continuously extruded soap bars in billets with the required length. In the past the widely diffused soap cutters are called "chain cutters" because they assembled a long rotating chain with many blades. The limitation of the chain cutters was the limited variation of the soap cutting length, so almost 30 years ago pneumatic and mechanical soap cutters replaced the chain cutters.

The last generation of soap cutters are characterized by two movements:

the blade moves up and down to cut the soap bar and, in the same time, the

blade moves horizontally with the same speed of the soap bar, to grant 90°

cutting. The principle of these two movements is used to build different models

of soap cutters, with a maximum speed up to 300 cuts per minute and with a

variable cutting range from 10 to 900 mm

8. Soap Finishing Line

8b. Soap Refining

8c. Mixers

8d. Soap Roll Mills

8e. Plodders

8f. Soap Cutters

8g. Soap Presses

8h. Chillers

8i. Accessories

8c. Mixers

8d. Soap Roll Mills

8e. Plodders

8f. Soap Cutters

8g. Soap Presses

8h. Chillers

8i. Accessories

>> INDEX

About 10 years ago, the advent of brushless motors at reasonable cost allowed to build a fully electronically soap cutter called "Easycut" with a rotating blade directly coupled to the servo-driven motor shaft that assures very accurate cuts for high-speed operations. Thanks to the extremely small cutting interval there is no need of a horizontal movement of the blade that starts and stops each cycle; so it is possible to produce High-Precision cut soap bars/billets. This type of soap cutter is able to cut up to 450 soap bars per minute.

EMBOSSING SYSTEM

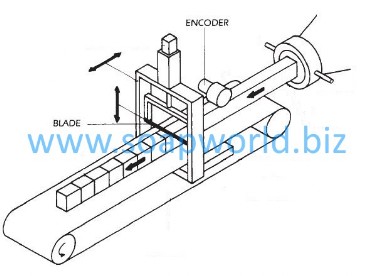

The embossing system is composed by 2 rolls (vertical and side rolls) or both 4 rolls able to print the soap bars. This device is assembled at the beginning of the soap cutter; thanks to an encoder the cut is done in

the correct position, so the printing is centered on the soap bars.

This system is an optional available on many models of soap cutting machines. The engraving rolls can be produced in brass or in cheaper materials like Teflon.

The embossing system is widely used to produce Laundry soap bars, "cut & printed" on 1 or 2 or 4 faces.

During the last decade the application of engraving system is increasing also for the natural soap with a sough look and like a cheaper alternative to soap stamping.