6d. Continuous Saponification Plant for Semi-Boiled Soap

Soap Manufacturing > 6. Industrial Soap Manufacturing

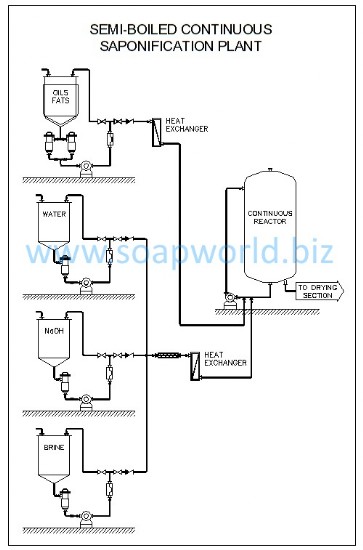

CONTINUOUS SAPONIFICATION PLANT for SEMI BOILED SOAP

This plant is similar to the Continuous Saponification plant for full boiled soap, but since this plant produce semi boiled soap, the washing section is not included, because the glycerin remains in the finished soap. This type of saponification plant is used for medium/big capacities and, due to the low viscosity the final soap at the end of the reaction is pumped in a soap vacuum dryer to remove the water in excess. The soap viscosity must be low because the Saponification Reactor has no mechanical movement; the soap is moved by a pump that recirculates soap with new raw materials that enter in the plant in continuous mode.

SAPONIFICATION PROCESS

Raw materials are pumped through Filters into the Continuous Saponification Reactor by the dosing groups. Each dosing group is composed of a pump, a flow-meter and related control valves. Oil, caustic soda solution, water and brine are fed to the Reactor through Heat Exchanger.

The Saponification Reactor works under pressure and at a temperature of about 130-140°C, the Heat Exchangers (for pre- heating) increase the temperature of raw materials. The recycle pump assures a high recycle delivery by means of the Reactor to obtain a perfect mixing, allowing to obtain the best conditions to complete the Saponification Reaction.

The soap at the outlet of the Saponification Reactor R2001 is sent to the following section.